Introduction

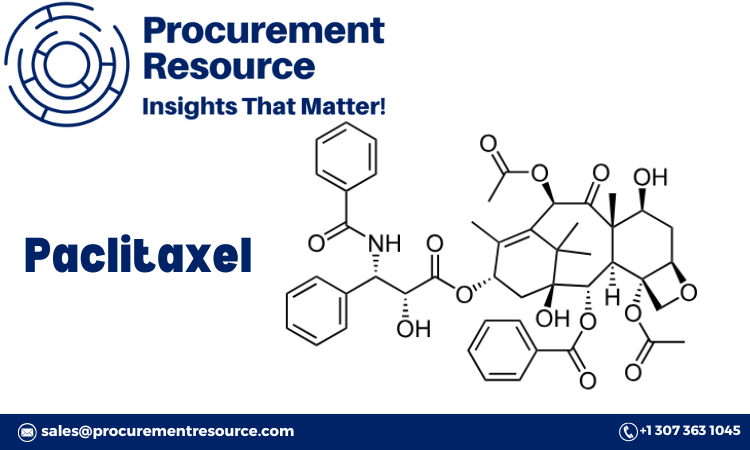

Paclitaxel is a chemotherapy drug widely used to treat various cancers, including breast, lung, and ovarian cancers. Derived primarily from the bark of the Pacific yew tree, Paclitaxel has become crucial in oncology due to its effectiveness in inhibiting cancer cell growth. Understanding the Paclitaxel Production Process with Cost Analysis is essential for pharmaceutical companies looking to optimize production efficiency and manage costs effectively. This report provides an in-depth analysis of the production process, procurement resources, market drivers, raw material requirements, and detailed cost breakdowns to support strategic decision-making.

Request For Free Sample: https://www.procurementresource.com/production-cost-report-store/paclitaxel/request-sample

Do you want to visit Haridwar? travel agents in Haridwar is the right place to plan your tour. You can book your tour from here.

1. Procurement Resource Assessment for Paclitaxel Production Process

The Paclitaxel Production Process relies on carefully sourced resources to maintain quality, sustainability, and cost efficiency. Securing high-quality raw materials and implementing an efficient supply chain is essential for reliable production. Here’s an overview of the procurement assessment for Paclitaxel production:

- Raw Material Sourcing: The primary source of natural Paclitaxel is the bark of the Pacific yew tree (Taxus brevifolia), although sustainable harvesting methods are critical due to the tree’s limited availability and ecological impact. Sourcing cultivated yew from sustainable plantations or utilizing alternative sources, such as the needles of other Taxus species, helps maintain an ethical and consistent supply.

- Synthesis of Paclitaxel through Plant Cell Culture: Due to the environmental concerns surrounding natural extraction, biotechnological methods, such as plant cell culture and semi-synthetic production, are increasingly used. Plant cell culture enables companies to cultivate Taxus cells in controlled environments, reducing dependency on natural resources and allowing for scalable production.

- Supply Chain and Logistics: Paclitaxel production involves multiple steps, including extraction, purification, and chemical synthesis. An efficient supply chain and logistics plan are crucial to manage the procurement and transportation of raw materials, maintain quality control, and minimize lead times, ultimately reducing production costs.

A comprehensive resource assessment enables companies to secure the necessary raw materials, streamline logistics, and ensure sustainable and cost-effective production of Paclitaxel.

Do you want to visit char dham? char dham tour operator is the right place to plan you Char Dham tour. You can book you tour from here.

2. Trypsin

While Trypsin is not directly involved in the production of Paclitaxel, it is widely used in the pharmaceutical industry for applications that complement drug manufacturing. Here’s a brief overview of Trypsin and its relevance:

- Protein Digestion in Pharmaceutical Production: Trypsin, an enzyme that breaks down proteins, is used in various processes within pharmaceutical production. For example, it aids in the digestion of proteins during cell culture processes and helps isolate active ingredients from raw materials, contributing to efficient and effective drug formulation.

- Use in Cell Culture Processes: In some biotechnological applications, Trypsin is employed to detach adherent cells from culture surfaces. This is relevant in plant cell cultures or other cellular processes that may accompany Paclitaxel production, particularly in research and development phases.

Understanding Trypsin’s role in pharmaceutical processes provides broader context for its applications and how enzymes contribute to efficient drug production and extraction processes.

Do you want to visit Indiar? tour operator in India is the right place to plan your tour. You can book your tour from here.

3. Market Drivers

The Paclitaxel market is driven by several key factors that influence demand and production trends. The main market drivers include:

- Increasing Cancer Incidence and Need for Chemotherapy: Cancer rates are rising worldwide, with breast, lung, and ovarian cancers among the most commonly diagnosed. Paclitaxel is an essential chemotherapy agent for these cancers, and as the number of cancer cases grows, so does the demand for Paclitaxel-based treatments, supporting long-term market growth.

- Adoption of Biotechnological Production Methods: Traditional methods of sourcing Paclitaxel from natural yew tree bark face ecological and sustainability challenges. As biotechnological methods like plant cell culture and semi-synthetic production gain traction, they improve production efficiency and cost-effectiveness, driving the market forward.

- Research and Development of New Therapeutic Applications: Ongoing research aims to explore new uses for Paclitaxel, such as targeted drug delivery systems and combination therapies. These advancements in oncology treatments are expected to broaden Paclitaxel’s applications, creating new market opportunities.

These market drivers reflect the growing importance of Paclitaxel in cancer treatment, as well as the role of technological innovation in supporting sustainable production and expanding therapeutic applications.

4. Raw Materials Requirements

The Paclitaxel Production Process requires specific raw materials and processing components to achieve high-quality results. Here’s a breakdown of the key raw materials:

- Taxus Species Biomass: The bark or needles of the Pacific yew tree or other Taxus species are the primary sources of Paclitaxel. Sustainable harvesting practices are crucial to maintaining ecological balance, and plant cell culture techniques offer an alternative to reduce environmental impact.

- Solvents and Reagents for Extraction and Purification: Various solvents and chemical reagents, such as methanol, ethanol, and dichloromethane, are used in the extraction and purification of Paclitaxel. These substances facilitate the separation of active compounds from other plant materials, ensuring the purity of the final product.

- Bioreactor Components for Cell Cultures: For companies employing biotechnological production methods, bioreactors and plant cell culture media are essential. These components allow for the controlled growth of Taxus cell cultures, enabling scalable and consistent Paclitaxel production.

Sourcing high-quality raw materials and employing sustainable production methods are essential for maintaining product quality and optimizing production efficiency in Paclitaxel manufacturing.

5. Costs and Key Process Information

The costs associated with the Paclitaxel Production Process are influenced by several factors, including raw material expenses, energy requirements, and regulatory compliance. Key cost components and process details include:

- Raw Material Costs: The price of Taxus biomass or plant cell culture media is a major factor affecting production costs. Sourcing from sustainable sources or cultivating in bioreactors may involve higher initial costs but can yield more stable long-term pricing.

- Labor and Operational Costs: Skilled labor is required for processes such as cell culture, extraction, and purification. Labor costs vary by region and may be influenced by regulatory compliance standards, such as those for Good Manufacturing Practices (GMP).

- Energy and Utilities Costs: The production process involves energy-intensive steps, including extraction and purification. Energy costs can be a significant component of production expenses, particularly for biotechnological methods that require specialized equipment and controlled environments.

- Regulatory Compliance and Quality Assurance: Given its use in cancer treatment, Paclitaxel production is subject to stringent regulatory standards. Compliance with FDA, EMA, and other regulatory bodies’ requirements ensures product quality and safety but can involve additional costs, such as facility audits and product testing.

A detailed understanding of these cost components enables businesses to optimize production efficiency, reduce expenses, and maintain compliance with industry standards in Paclitaxel manufacturing.

6. Looking for an Exhaustive and Personalized Report That Could Significantly Substantiate Your Business

For companies looking to gain a competitive edge in the Paclitaxel market, an exhaustive and personalized report can provide in-depth insights tailored to specific business needs. A customized report offers a range of benefits, including:

- Detailed Market Trends and Forecasts: Access comprehensive data on market trends, emerging therapeutic applications, and competitive landscape assessments. These insights help businesses capitalize on opportunities and align their strategies with industry developments.

- Cost Optimization Strategies: An analysis of production costs and resource utilization allows companies to identify potential cost-saving measures, such as transitioning to biotechnological production methods or optimizing the supply chain.

- Regulatory and Compliance Guidance: Navigating complex regulations in pharmaceutical manufacturing is essential. A customized report provides detailed information on industry requirements and ensures your business complies with local and international guidelines for cancer treatment drugs.

- Strategic Recommendations for Business Growth: Tailored insights based on your production capabilities, target markets, and operational goals can provide actionable recommendations for growth and competitiveness. These strategic insights guide decision-making and enhance market positioning.

Investing in a customized report provides a foundation for strategic planning and allows companies to make data-driven decisions based on comprehensive market analysis and tailored insights. With a thorough understanding of the Paclitaxel Production Process with Cost Analysis, businesses can position themselves for success in the rapidly evolving oncology market. Whether it’s expanding production, improving efficiency, or exploring new therapeutic applications, a personalized report can significantly substantiate your business strategy and support long-term growth in the pharmaceutical sector.

Contact Us:

Company Name: Procurement Resource

Contact Person: Benking sley

Email: sales@procurementresource.com

Toll Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA